How well a thread sewing machine processes folded signatures in offset printing depends largely on the feeder system. A high degree of reliability when separating and opening signatures ensures the efficient operation of the sewing machine and allows its full capabilities to be utilized. For its thread sewing machines for offset printing, Smyth uses its patented 4D feeder.

Four special features: how the Smyth 4D feeder got its name

The “4D” in the name of the patented Smyth 4D feeder stands for its characteristic four special features.

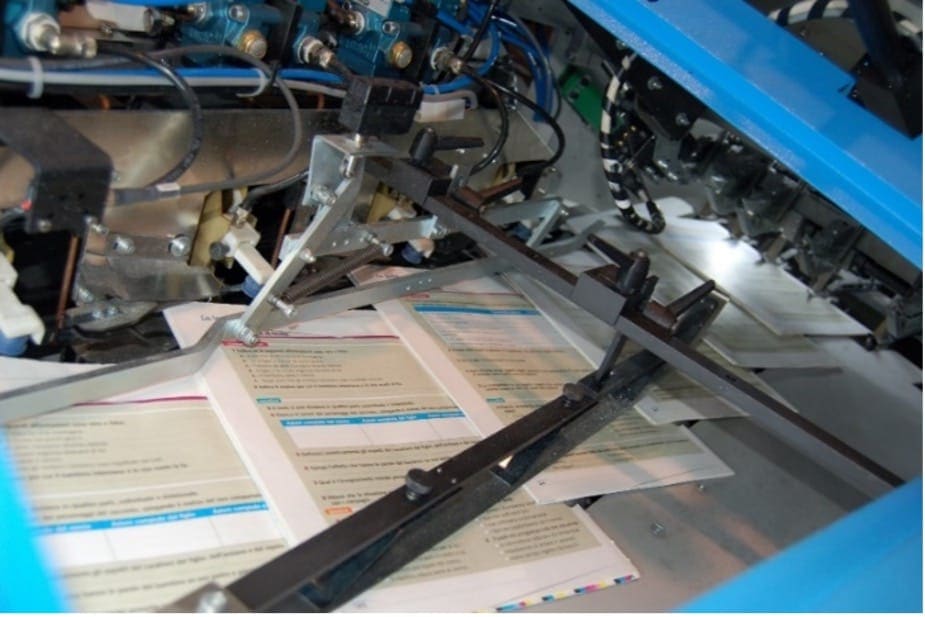

Feature 1: Shingled stream

In the patented Smyth 4D feeder, the folded signatures are not conveyed individually. Instead, they overlap as a shingled stream, which is conveyed on slow-moving conveyor belts. Compared to a Headop feeder with sequential signature conveyance, the patented Smyth 4D feeder reduces the signature conveyance speed by 50% – with the same sewing production output. Shingled conveyance reduces the risk of the signatures fluttering at high production speeds, especially when thin paper is used.

The low conveyance speed also increases the contact time of the opening suction cups with the signature. The concurrent movement of the suction cups further increases the contact time. The result is that the signatures are opened in a gentle, very precise manner – even if porous paper and strong head perforations are used and static electricity is present.

Porous paper can also be opened according to the Venturi principle if needed.

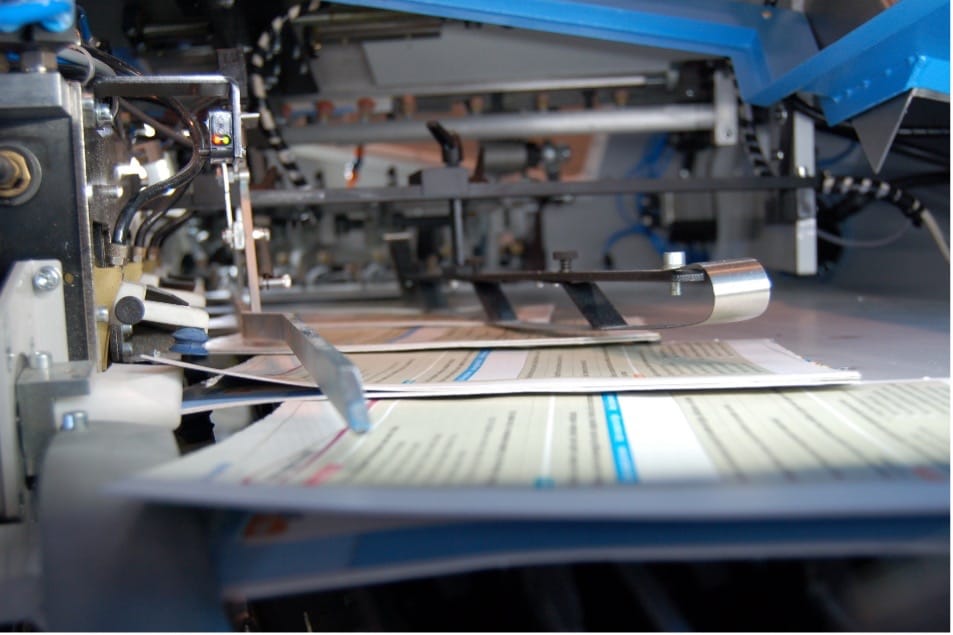

Feature 2: Rotating suction cups

The four upper and lower suction cups of the 4D feeder perform a combined movement to open the signatures:

- Concurrent movement in the conveyance direction and at the same speed of the signature in the feeder in order to increase the contact time with the paper, as well as

- Rotational movement to ensure that the corners of the signature are gently opened.

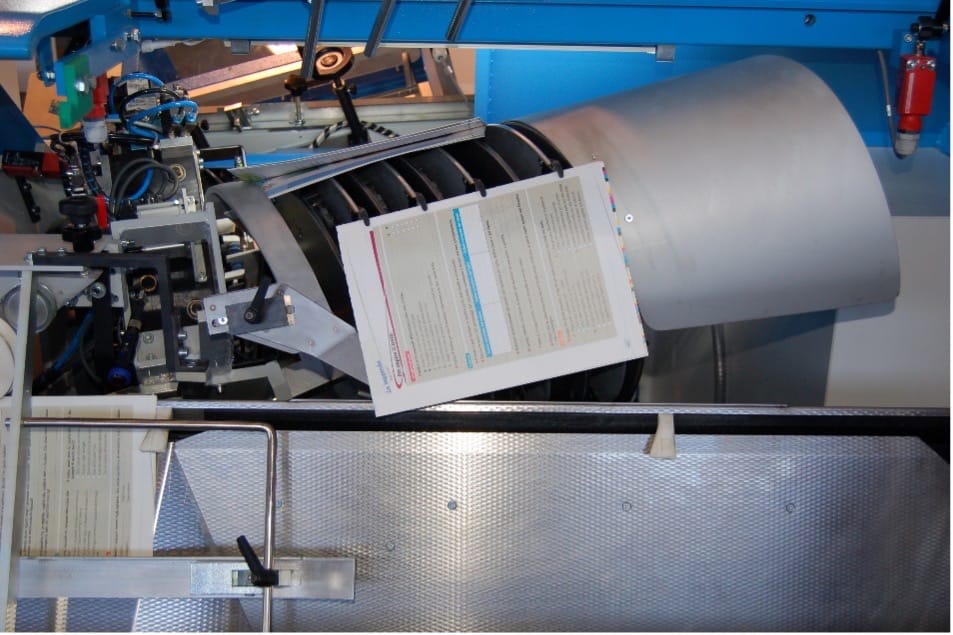

Feature 3: Curve guide device holds open the center of the signature

The opened signature is held open in the center by a curve guide device. This curve guide element and the grippers on the gutter of the signature ensure that the signature is guided from the feeder to the mobile saddle. The signature is thus transferred in a controlled and extremely reliable way – and is never in “free fall”.

Feature 4: Angled position of the signature

This unique 4D feeder system also differs in the inclination of the signature within the shingle. This exposes the corners of the signature to the opening suction cups. As it is transferred from the feeder to the mobile saddle, only the upper corner of the signature, rather than the entire front side the signature, comes into contact with the mobile saddle. This ensures that the signature opens much more easily and reliably.

The patented Smyth 4D feeder guarantees a high degree of reliability in the separation and opening of signatures and ensures maximum production reliability.

Integrated griper fold opener

The integrated gripper fold opener increases the versatility of the 4D feeder. Once the gripper fold opening function is selected via the control, it is immediately ready for use – without any additional set-up. This even allows the opening of signatures with varying grip fold widths. It is also possible to switch between pre- and post-fold signatures within a book block.

Models with the 4D feeder

The following Smyth sewing machines for industrial sewing in offset printing are equipped with the 4D feeder: